The first day I started sold a Testarossa, and later that day a 308 Cabriolet to the Barcardi family, their son crashed the brand new car the same week, later they came back and got another one from me she was sittting in the showroom with a bow, we used to hang out on weekends at the Mutiny in Coconut Grove, at Ends & Bitters, Big Daddie's on Le Jeune Rd, they had the best Rock bands live, Faces In The Grove, Studio 51 Ft Lauderdale, Pete & Lenny's, Penrod's, Casanovas, Firehouse Four, Stefano´s, Sundays on the Bay, times of KC and the Sunshine Band, The Bee Gees, Scarface.

Rock and Roll was my favorite but to meet chicks you must learn a dance, and dances like "Bump", "Boogaloo", and the "Robot" where the thing. By the late 70´s the Hustle, then Disco got popular with the movie Saturday Night Fever, I hated Disco, to me Dsico eas for pussies but most girls liked it, everyone had to dress up to fit in, polyester suits, stamped pictures shirts, platform shoes, Disco balls & lighted dance floors invaded clubs, to me racing was my thing then didn´t care much for dancing.

Rock and Roll was my favorite but to meet chicks you must learn a dance, and dances like "Bump", "Boogaloo", and the "Robot" where the thing. By the late 70´s the Hustle, then Disco got popular with the movie Saturday Night Fever, I hated Disco, to me Dsico eas for pussies but most girls liked it, everyone had to dress up to fit in, polyester suits, stamped pictures shirts, platform shoes, Disco balls & lighted dance floors invaded clubs, to me racing was my thing then didn´t care much for dancing.

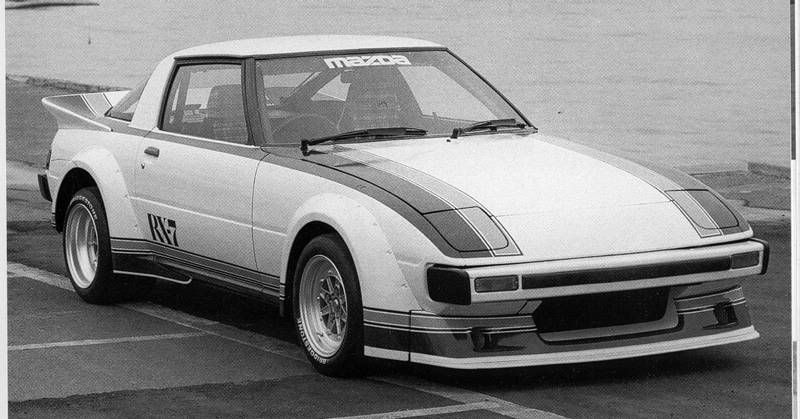

I got lucky anyway, one day a trade-in came and I bought it for racing, I raced a Mazda RX-7 in most of the backstreets of South Florida, illegal quarter mile race that was, my Racing Beat equipd rocket raced Porshes, Ferraris, Corvettes, Camaros, Mustangs, everyone had to do with my white Monster most people got clueless on how such a small unknown engine brand car who spitted fire out of the mufler

in most gears won most of the time, what people didn´t know is that the amazing technology on the Wankel german pattented engine was bought by mazda and installede in the RX_/ that made the car unbeatable....we also used to go on Motorcycles also to the classic Daytona 500, on Bike week, and with my friends every year to the Miami Grand Prix races . Those were the good old times ....

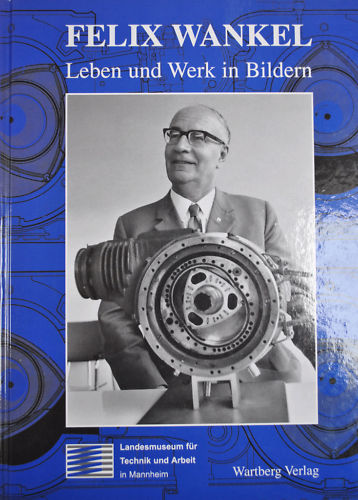

History of the Wankel Rotary Combustion Engine

Designs for rotary engines were proposed as early as 1588 by Ramelli, though it took the development of the Otto cycle engine in 1876 and the advent of the automobile in 1896 to set the stage for the modern rotary combustion engine1.

NSU Spider

NSU Fiat 500 Spider Sport Body By Glaser Manufactured In 1938

NSU Spider

NSU Fiat 500 Spider Sport Body By Glaser Manufactured In 1938

Dr Felix Wankel conceived his idea of a rotary engine in 19241. In 1933, he applied for a patent for a DKM (Drehkolben Maschine or single-rotation engine), the first type of RCE. This type had the distinctive feature of an inner rotating housing and rotor moving in circular motion around a fixed central shaft1. Fiat NSU Balilla (1936) - Oldtimer kaufen | Zwischengas

Fiat NSU Balilla (1936) - Oldtimer kaufen | Zwischengas

Fiat NSU Balilla (1936) - Oldtimer kaufen | Zwischengas

Fiat NSU Balilla (1936) - Oldtimer kaufen | Zwischengas

In the following years, Wankel mostly made his way by ingenious work on rotary valves and sealing technology for Lilienthal, BMW, DVL, Junker, and Daimler-Benz1. During this time he developed various DKM prototypes and also rotary pumps and compressors. When the French army entered Germany in 1945, his workshops and research were destroyed and he was imprisoned until 19461.

During the Allied occupation, Felix Wankel began secretly writing his book on the organization of rotary piston engines. He was able to rebuild a research operation by 1951 when he interested NSU (a German car & motorcycle manufacturer18,19) in further development1.

By 1957 NSU had convinced Wankel to abandon the single rotation DKM design and all further research work was concentrated on the planetary rotation KKM type engine (Kreiskolbenmotoror planetary rotation motor)1. The outer rotor now became stationary and the inner rotor spun on an eccentric shaft8. This design proved to be easier to manufacture, cool, and maintain than the DKM1, and is the basis of the modern Wankel engine1.

The first truly functional Wankel RCE was a DKM type that ran in February 19571. By May a prototype was able to run for two hours and produce 21 bhp1. The first KKM engine ran on July 7, 19581.

Basic Operation of the Rotary Combustion Engine

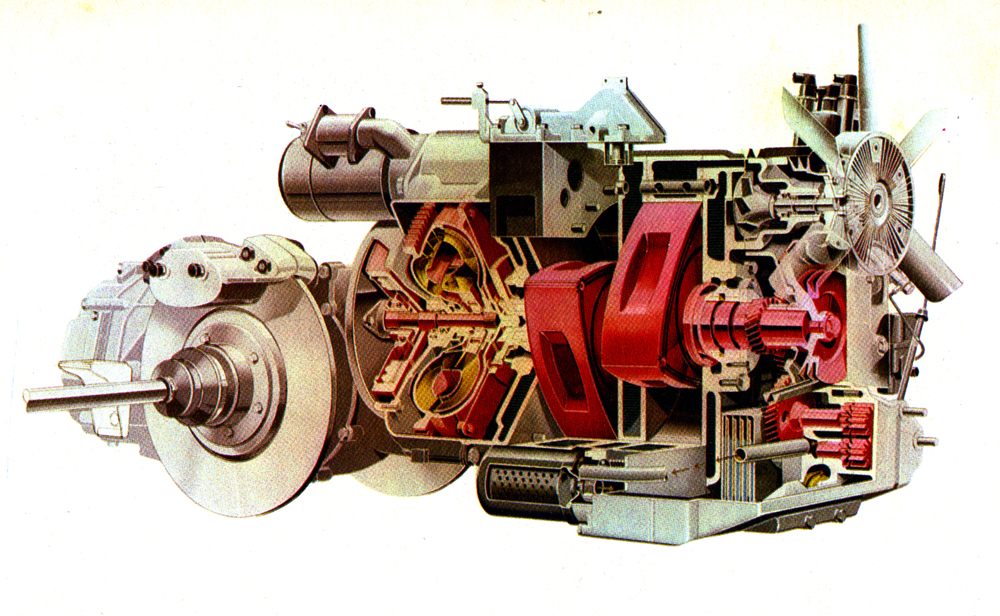

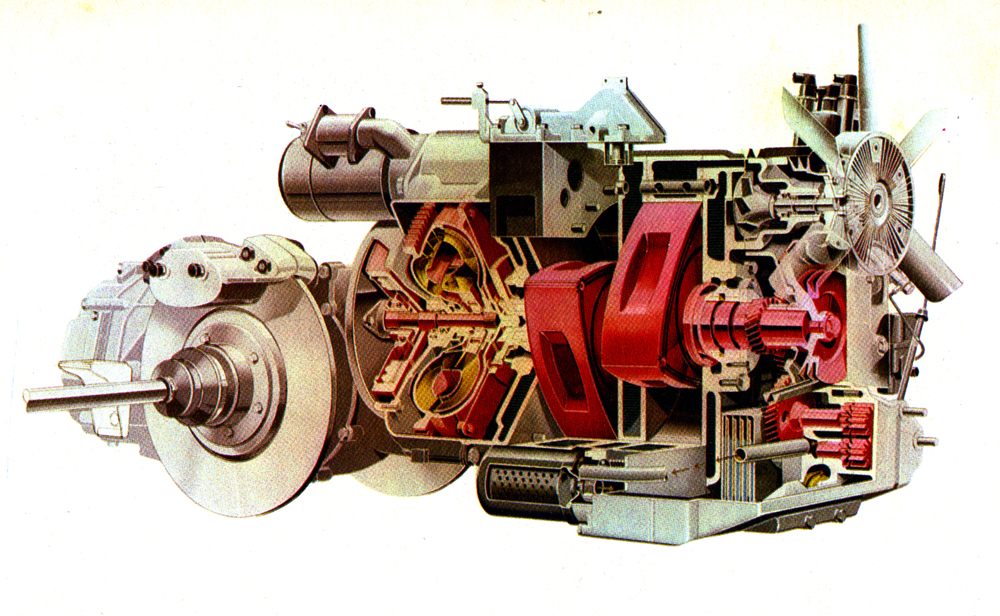

The Wankel rotary system operates on the basis of the Otto, or four stroke cycle; in other words it completes an engine cycle in four stages: intake, compression, power, and exhaust6. However, it does not use a reciprocating piston to transfer energy, but instead uses a rotor turning within a fixed housing7.

The rotor has three convex faces, each of which acts like a piston. Each face of the rotor has a pocket in it, which increases the displacement of the engine, allowing more space for air/fuel mixture7.

At the apex of each face is a spring loaded metal blade that forms a seal to the outside of the combustion chamber. There are also metal rings on each side of the rotor that seal to the sides of the combustion chamber7.

The rotor has a set of internal gear teeth cut into the centre of one side. These teeth mate with a gear that is fixed to the housing. This gear mating determines the path and direction the rotor takes through the housing7.

The housing is roughly oval (sometimes likened to a fat figure of eight15), or epitrochoidal in shape7. This shape is generated by rolling a circle around another circle1; the external rolling circle is half the size of the generating circle1. The shape of the combustion chamber is designed so that the three tips of the rotor will always stay in contact with the wall of the chamber, forming three sealed volumes of gas7.

The intake and exhaust ports are located in the peripheral or end housing. There are no valves in these ports. The exhaust port connects directly to the exhaust, and the intake port connects directly to the carburettor.

As the rotor turns, its tips pass the ports in the housing. As one tip passes the intake port in the rotor housing the resulting drop in pressure starts to draw in the fuel air mixture. When the next tip passes the intake port the mixture is captured and starts to compress. As the chamber continues around the housing it encounters the spark plug and the mixture inside it is fully compressed.

NSU Motorenwerke

NSU Prinz 4.jpg) The spark plug fires and the mixture starts to expand imparting the pressure energy in the burning mixture to the output shaft. As the rotor continues on, the tip passes the exhaust port and the burnt mixture starts to leave the chamber. This completes the four cycles for chamber ‘A’. In the meantime chamber ‘B’ and ‘C’ are completing various cycles of this same sequence simultaneously.

The spark plug fires and the mixture starts to expand imparting the pressure energy in the burning mixture to the output shaft. As the rotor continues on, the tip passes the exhaust port and the burnt mixture starts to leave the chamber. This completes the four cycles for chamber ‘A’. In the meantime chamber ‘B’ and ‘C’ are completing various cycles of this same sequence simultaneously.

NSU Motorenwerke

NSU Prinz 4

.jpg) The spark plug fires and the mixture starts to expand imparting the pressure energy in the burning mixture to the output shaft. As the rotor continues on, the tip passes the exhaust port and the burnt mixture starts to leave the chamber. This completes the four cycles for chamber ‘A’. In the meantime chamber ‘B’ and ‘C’ are completing various cycles of this same sequence simultaneously.

The spark plug fires and the mixture starts to expand imparting the pressure energy in the burning mixture to the output shaft. As the rotor continues on, the tip passes the exhaust port and the burnt mixture starts to leave the chamber. This completes the four cycles for chamber ‘A’. In the meantime chamber ‘B’ and ‘C’ are completing various cycles of this same sequence simultaneously.

The output shaft has round lobes mounted eccentrically on it; each rotor fits over one of these lobes. As the rotor follows its path around the housing, it pushes on the lobes. Since the lobes are mounted eccentrically to the output shaft, the force that the rotor applies to the lobes creates torque in the shaft, causing it to spin.

NSU Wankel Spider

Alfa Romeo NSU Prinz 30 Saloon - 1961

To compare with a four stroke piston engine:

- The RCE Rotor replaces the reciprocating piston.

- The RCE Eccentric Shaft replaces crankshaft and connecting rods.

- The RCE Peripheral Housing replaces the cylinder block.

MAZDA COSMO CON NSU ROTARY ENGINE TECHNOLOGY

NSU RO 80

1975 Hercules Wankel Motorcycle

Examples of Rotary Engined Motorcycles

The first motorcycle application of the Wankel engine emerged from the IFA/MZ factory, from 1960.

Hercules W2000 (DKW)

The Hercules (Herkules) works have produced motorcycles for nearly 100 years. They belong to the Sachs group who are probably most well known for producing automotive products, particularly shock absorbers and small engines. Sachs was one of the first licensees of the Wankel rotary engine in 1960.  They developed and built more than 35,000 rotary engines, mostly for stationary purposes The biggest engine produced by Sachs was the 294 cc KM 914, originally intended for use in generators and snowmobiles. This KM 914 was the basis of all Hercules and later BSA (and Norton thereafter) rotary motorbikes.

They developed and built more than 35,000 rotary engines, mostly for stationary purposes The biggest engine produced by Sachs was the 294 cc KM 914, originally intended for use in generators and snowmobiles. This KM 914 was the basis of all Hercules and later BSA (and Norton thereafter) rotary motorbikes.

They developed and built more than 35,000 rotary engines, mostly for stationary purposes The biggest engine produced by Sachs was the 294 cc KM 914, originally intended for use in generators and snowmobiles. This KM 914 was the basis of all Hercules and later BSA (and Norton thereafter) rotary motorbikes.

They developed and built more than 35,000 rotary engines, mostly for stationary purposes The biggest engine produced by Sachs was the 294 cc KM 914, originally intended for use in generators and snowmobiles. This KM 914 was the basis of all Hercules and later BSA (and Norton thereafter) rotary motorbikes.

The first Hercules W 2000 was shown at the German IFMA motorbike show in 1970. In addition to the adapted KM 914 engine it used a BMW gearbox and driveshaft. Only one prototype was produced.

In 1973 Hercules built 50 W 2000 in a "pre-series" and sold them only to Hercules dealers. It had a KC 24 engine; this was based on the KM 914 but had a six-speed gearbox with chain type final drive.

Production began in 1974 with a revised KC 27 engine. The 1976 model of the W2000 was updated to include an oil-injection, "auto-mix" system, which eliminated the need to hand mix of fuel and oil together. This new model was an instant success, and sales of the W-2000 Rotary rose sharply. Once again, new dealers joined the Rotary network, and it seemed as though the Hercules W-2000 Rotary had found its place in the motorcycle family. Even though increased sales and new dealers were on the rise, on November 25, 1976 out of nowhere Hercules W-2000 motorcycle production came to an abrupt halt.

Production began in 1974 with a revised KC 27 engine. The 1976 model of the W2000 was updated to include an oil-injection, "auto-mix" system, which eliminated the need to hand mix of fuel and oil together. This new model was an instant success, and sales of the W-2000 Rotary rose sharply. Once again, new dealers joined the Rotary network, and it seemed as though the Hercules W-2000 Rotary had found its place in the motorcycle family. Even though increased sales and new dealers were on the rise, on November 25, 1976 out of nowhere Hercules W-2000 motorcycle production came to an abrupt halt.

Nothing was wrong with the Hercules W-2000 bike or engine; it ran perfectly. The reason production stopped was because it did not meet a set monthly quota by 25 units.

After production was halted Sachs sold the tooling machines for the rotary engines it produced to BSA/Norton .

SUSUKI RE5 RE-5 Rotary Wankel '76 -76

Suzuki RE-5

In 1970 Suzuki obtained a Rotary license from NSU/WANKEL and placed their full engineering team on an intensive Rotary Engine Development Program. By mid 1973, they had taken their secret RX-5 (Rotary Xperimental - 500cc) project from the drawing board to a fully-operational, RCE powered motorcycle.

The new RX-5 prototype made its grand debut at the Tokyo Motor Show in January of 1974. The response was positive, and, in light of rotary development by other manufacturers, notably Yamaha (RZ-201) and Sachs/Hercules, Suzuki decided to go into full production with a slightly modified and refined version of the RX-5 prototype, re-named the RE-5. By June of 1974, the first RE-5s came trickling off the assembly line, due in part to a series of teething and initial supply problems. In September of 1974, the RE-5 Rotary made its simultaneous debut in Germany, England, France, Spain, Belgium, and the United States

A large number of RE-5 orders were taken. However, due to production problems, Suzuki had to postpone delivery dates. This led to customer order cancellations and started rumors about reliability. However, by the middle of January 1975, the RE-5 Rotary had made it to the showroom floor.

A few months later a series of carburetor problems surfaced, and Suzuki issued special service bulletins to correct this through a "Quiet Recall" Program. Though the carburetor problem was simple enough to repair, word of mouth exploited the situation and blew it far out of proportion (to such an extent that 1975 RE-5 sales took a nose dive) In September the new and improved 1976 model made its debut and sales picked up somewhat; but unfortunately it was not enough. Suzuki quietly ceased production a few months later

1934 NSU 201 ZDL MOTO

Van Veen OCR 76-78

Dutch importer Henk van Veen grafted a Comotor engine (the powerplant used inNSU /Citroen ’s Birotor joint venture) to a Moto Guzzi frame1. Announced in 1976 it was produced until 19781.

his heavy bike--over 700 lb (320 kg)--could hit 125 mph (200 kph) in just 16 seconds and reached 135 mph (215 kph) in tests. The OCR 1000 cost $15,000+ by late 1978, about the time production ended after some 30 units were built.

his heavy bike--over 700 lb (320 kg)--could hit 125 mph (200 kph) in just 16 seconds and reached 135 mph (215 kph) in tests. The OCR 1000 cost $15,000+ by late 1978, about the time production ended after some 30 units were built.

Norton

Norton's involvement with rotary combustion engines began with the amalgamation of Norton-Villiers and BSA-Triumph to form Norton-Villiers-Triumph (NVT) in 1973. The Birmingham Small Arms Co., Ltd., (BSA) had been designing & testing RCE prototypes since 1969. The research programme carried on unhindered until the collapse of NVT in 1975. Fortunately, the then chairman, R.D. Poore, retained the rotary project and a small team continued work on the prototype.

25 Mark I prototypes were built in 1979. In 1981 a Mark II appeared which eventually went into production as the Interpol II. Subsequent Norton rotary models are listed below in chronological order:

The second prototype MZ, using an air-cooled 175cc Wankel motor; the KKM 175 L

Classic - 1987-88 - A civilian (unfaired) version of the Interpol II, Just 100 (other sources say 101 or 105) of these air-cooled rotary machines were put on sale in 1987 following a change of ownership of Norton motors.

Commander - 1988-94 - The water-cooled successor to the Classic, returning to the full fairing of the Interpol II. Only 239 of the early type were produced. The 1992 version had more practical detachable panniers by Krauser. Only 61 of these were produced.

Feature Article from Hemmings Sports & Exotic Car

July, 2010 - Jim O'Clair

It took over 18 years for Norton to adapt a Wankel rotary engine into their own motorcycle chassis. Research and development on the rotary Wankel began during 1969 at the BSA Group Research Centre in Kitts Green. The Wankel engine was based on a Sachs air-cooled rotary used in the German-built DKW/Hercules model W2000.

A final agreement with Audi/NSU to market the rotary engine in a production motorcycle was signed in August of 1972, and the project survived the absorption of the Norton Villiers Group into Triumph/BSA in 1973. A Norton prototype was announced in several motorcycle magazines in 1974, but they did not reach actual production until 1987. They were first produced as an air-cooled version in the Norton Interpol 2 police model P41. In 1988, Norton changed to a water-cooled rotary and released the police/military touring model P52 Interpol 2A. They were made available to the public as a Commando 588 model P53 in the same year.

The new Commandos were not well received by the riding public, and sales were sparse; however, Brian Crighton, an employee of Norton, spent many off-hours tweaking the rotary engine to squeeze more horsepower and performance out of it. In its stock configuration, the Wankel produced about 85hp; however, Crighton was able to tweak that up to 96hp with some modifications. This convinced the management that a rotary-propelled race bike was feasible, and although he was not put in charge of any Norton racing motorcycle program per se, Brian was allowed to scavenge parts from used and damaged police bikes and continue to work on the prototype on his own time. With the help of a few friends, Crighton was able to modify the carburetion and cooling system and beef up the performance to over 125hp while retaining the stock 9.2:1 compression.

After testing at over 155 MPH, the team addressed some handling issues by having a custom Spondon aluminum frame built for it. This lightened the bike and increased the horsepower even further. The Norton Wankel race bike dubbed the RCW588 received John Player Special sponsorship in 1989 and went on to set several speed records and achieve superbike victories, including the 1992 Isle of Man Senior TT under Steve Hislop and a 1994 Superbike win under Ian Simpson. Norton factory racers Ron Haslam and Steve Spray also enjoyed success on 588cc rotary-powered Norton racers.

On the retail side, Norton continued to market the Wankel-engined machines as the P53 Commander touring bike and the P43 Classic sport bike. Less than 110 of the Classics were built using the air-cooled version of the rotary engine. In 1989, the model P55 John Player Special Norton F-1 was produced, and later a P55B model F-1 Sport. The F-1 was a less powerful version of the RWC588 race bike, at 94hp, although it was mounted on the same Spondon frame. The F-1 weighed less than 425 pounds, and this made it very racy. Quarter-mile times were in the mid-11s, and top speed was about 155 MPH. An additional rotary-based model, the Interplus was introduced in 1992 as a sport-touring bike. Race track success did not equate to unit sales, however. The rotary Nortons did not survive for very long in touring bike market, and the F-1 enjoyed only modest success.

Nortons continue to draw attention at many classic motorcycle auctions and shows today. That interest has recently been fueled by the release of the new Norton 961SS Commando and SE models by the new Norton Motorcycle Company. The iconic Norton motorcycle will also be one of our featured marques at the Hemmings Sports & Exotic Car Show on August 7, 2010, at the Saratoga Auto Museum in Saratoga Springs, New York.

F1 - 1990-94 - This was a super sports development, being a road going version of the successful RCW 588 racing machine. Only 140 were ever made. Due to the high cost of the F1, a cheaper version, the F1 Sports, became available in mid-1992. This version, with revised carburation, was said to have run more smoothly than the original F1 where the carburettors were prone to overheating. 70 F1 Sports models were produced.

By 1990 the kudos surrounding the F1, combined with engine manufacturing and the Commando spare parts business, meant that Norton’s prospects appeared to be good. However, a DTI investigation into the Group’s activities was launched in January 1991, which resulted in proceedings being brought against a number of the directors. Norton Group plc was subject to a compulsory winding up order on 13thOctober 1993.

The Norton name and motorcycle assets were sold; the rotary engine technology is now owned by Mid-West Engines of Gloucester.

Why Use An RCE?

Advantages

There are numerous advantages in using the Wankel RCE in place of a reciprocating piston engine. In terms of motorcycle use, the superior power to weight ratio of the RCE stands out. Because each combustion event lasts through 90-degrees of the rotor's rotation, and the output shaft spins three revolutions for each revolution of the rotor, each combustion event lasts through 270-degrees of the output shaft's rotation. This means that a single-rotor engine delivers power for three-quarters of each revolution of the output shaft. Compare this to a single-cylinder four stroke engine, in which combustion occurs during 180 degrees out of every two revolutions, or only a quarter of each revolution of the crankshaft. The wankel engine also breaths extremely well at high RPM since there are no valves getting in the way of the intake and exhaust ports.

In addition, the reduced number of moving parts as compared to a two or four stroke piston engine enhances the RCE’s durability and efficiency. All the parts in a rotary engine spin continuously in one direction, rather than violently changing direction like they do in a conventional engine. The reduced number of components cuts frictional losses and allows direct energy transfer from the rotor to the output shaft. Lack of reciprocating weight means that RCE’s run more smoothly than conventional engines.

There are no valves so failure in this area is all but eliminated. The rotors are cast iron and unlike pistons are nearly impossible to melt. They can be made from heavy cast iron precisely because they do not reciprocate, thereby reducing cost. Since the rotors spin at one-third the speed of the output shaft, the main moving parts of the engine move slower than the parts in a piston engine. This also helps with reliability.

This inherent durability has been amply demonstrated by Mazda’s use of a turbo-charged 800 HP two rotor 10,000 RPM racing engine of stock displacement.

The engine does not fail in 'hand genade' mode as is common with reciprocating engines. In fact, the worst reliability issue is overheating, but the engine will still run – another reason why they are used in aircraft.

Disadvantages

There appears to be very few disadvantages in using the RCE. Initially there were several common problems but these have mostly been overcome during subsequent development. These generic problems comprised:

- Sealing of the rotor tips.

- High fuel consumption. RCE’s typically consumed more fuel than piston engines because the thermodynamic efficiency of the engine is reduced by the long combustion-chamber shape and low compression ratio7.

Overheating. In a sequence similar to an axial-flow turbine engine, gases in the rotary engine flow in one direction only; inducted gases following the direction of rotor rotation through compression and then expansion to exhaust. Thus the induction/compression section of the rotor housing remains relatively cool whereas the expansion/exhaust section is much hotter and requires careful management of cooling. Early automobile engines suffered excessive rotor seal wear due in part to differential expansion caused by this variation distorting the ideal machined profiles.

Aside from these general mechanical issues, there are also cost disadvantages. To set up and manufacture these engines requires a great deal of initial funding. These costs would need to be covered through sales, but recent history (with particular reference to Suzuki’s RE5) has proven that rumours of unreliability can badly affect sales figures.

Finally, the issue of maintenance comes to mind. Although the rotary engine is a relatively straightforward piece of technology, the author would estimate that very few, if any, technicians have had any practical experience of rotary engine maintenance. As motorcycles become more mainstream, this may be enough to put off a potential purchaser.

Is There a Place For RCEs in Current Motorcycle Development?

Rotary engines are ideal for motorcycle use. Their relatively small size v power output allows a high powered engine to be fitted into a small space (i.e. a motorcycle frame). They have relatively few moving parts and these rotate rather than reciprocate, allowing smooth operation. This is also a benefit for motorcycle applications. They are reliable, and do not fail catastrophically like piston engines (one of the main reasons why they are popular as light aircraft engines). They are therefore suited to motorcycle racing where great steps are taken to ensure that this kind of failure does not happen.

Recent developments, led by companies such as Mazda (who have been producing rotary cars for several years) have meant that the initial mechanical disadvantages noted in section 5.2 have been overcome. For example:

- Ceramic rotor tip seals have been developed that are so hard and smooth that they exhibit no noticeable wear rate. Mazda have demonstrated an engine life of 20,000 hours running such seals in a generator set operating at 3600 RPM.

- The new Mazda RX8 engine uses side exhaust ports rather than the peripheral ports favoured in earlier RCEs. This is reputed to be much more economical as the design allows residual un-burned fuel to be re-circulated to the next combustion cycle. The exhaust port timing is also modified in the RX8 engine to allow a longer expansion cycle recovering more energy from the fuel.

- High temperature, 500 degree Fahrenheit, teflon encapsulated silicone water jacket seals and oil scraper O-rings have been developed. These increase the ability of the engine to better withstand inadvertent overheating.

Development of the RCE has been achieved in about one third of the development time of five major propulsion systems, three of which are internal combustion piston engines. Most of the RCE motorcycles discussed in previous sections appear to have failed due to bad luck and bad marketing rather than poor design – had Norton’s F1 remained in production then current technology might be very different. Further advances in RCE technology include the use of diesel & hydrogen fuels, and even steam.

Despite these advances the RCE is not used in any current production motorcycle. The RCE’s exclusion from racing has not helped in this regard. Section 2.3.1 of the FIM technical regs for MotoGP states, “Engines may operate on the two stroke or four stroke principal only”. Since the racing world is such an influence on the UK motorcycle market, it is difficult to see how things will change until these engines are allowed to be used in such competitions.

While rotary use in cars and aircraft continues to grow, motorcycle manufacturers remain unconvinced. The failures of the 70’s and 80’s have not been forgotten. The comeback of the rotary engines is not far off, but manufacturers are likely to ‘wait and see’ before committing resources to further development. All eyes will be on Mazda’s new RX8 sportscar which is due for launch in 2003.

References

1. www.monito.com/wankel - 9/12/02

2. www.loginet.nl/europa/home.htm - 9/12/02

3. home.earthlink.net/~rotaryeng/increadable-rotary.txt - 10/12/02

5. home.earthlink.net/~rotaryeng/how-wank-works.jpg - 10/12/02

7. www.howstuffworks.com/rotary-engine.htm - 11/12/02

8. www.nsumotor.onlinehome.de/wgeschicht.htm - 11/12/02

9. www.rotaryaviation.com - 11/12/02

10. www.invention.com/barrera.com - 11/12/02

11. www.business2.com/archives/mag/0,1059,317,00.html - 11/12/02

12. www.rotaryengineillustrated.com - 12/12/02

13. www.conceptengine.tripod.com/conceptengine/id2.html - 12/12/02

15. www.infoplease.com/ce6/sci/A0858858.html - 12/12/02

16. www.rotaryrecycle.net - 12/12/02

17. www.hercules.de - 12/12/02

18. www.der-wankelmotor.de/motoraeder/Hercules/hercules.html - 12/12/02

19. silverstone.fortunecity.com/Porsche/651/history.html - 14/12/02

20. http://www.nortonownersclub.org - 14/12/02

21. www.newsrelease-archive.net/coi/depts/DTI/coi5890d.ok - 14/12/02

23. www.fim.ch - 14/12/02

24. www.eskimo.com/~ghawk/ - 14/12/02

No comments:

Post a Comment